what is hrc fuse link

What we need to know is that there is a limit to the current in a circuit. Once the circuit current exceeds the specified limit, it can cause major defects in the system. Fuses are only used in electrical circuits to protect against this defect. Therefore, using copper wire melts when the current exceeds its capacity and further avoids overloading the working equipment so as not to lose the view. This article tells you the basic knowledge, structure, working principle, application, reasons for fuse blowing, solutions, and protective measures to prevent fuse blowing of HRC fuse link.

HRC fuse is a High Rupturing Capacity fuse, also known as the current limiting fuse. Current-limiting fuse is a type of high-voltage fuse. Current-limiting fuses are divided into resistance current-limiting and arc reactance conversion current-limiting. Resistor current limiting limits the current value in the circuit to a certain amplitude. It will not exceed a certain value regardless of short circuit or not.

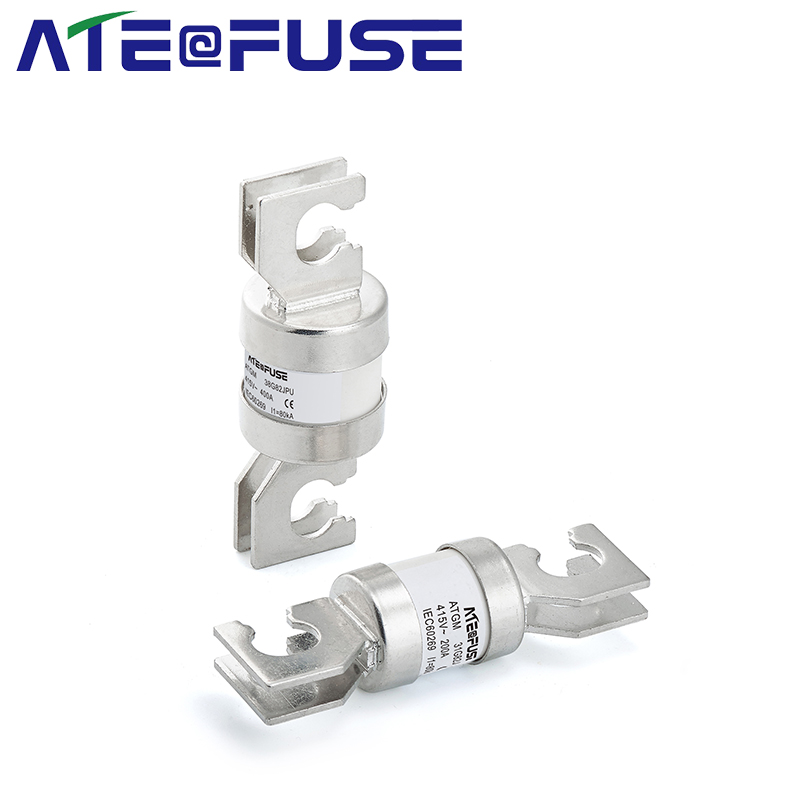

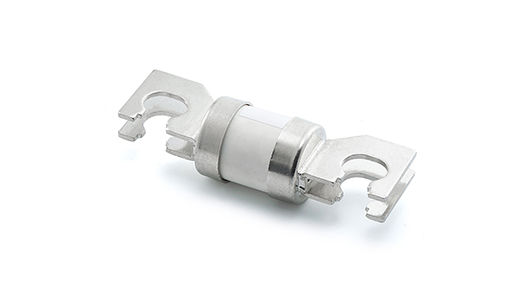

HRC fuse link structure

Current-limiting fuses have two melt structures, an in-line melt and a spiral wound melt. After arcing in the in-line melt, the arc reactance increases as the arc lengthens. And gradually change the phase. Spiral melt uses spiral reactance transformation to change phase. The two create zero rest, causing the voltage and current to cross zero at the same time. The phase shift extinguishes the arc before the current reaches its peak value. This current limiting ability when extinguishing the arc varies greatly. It can be seen that the type and structure of the current-limiting fuse must be considered in the power supply design. Fuses that can limit the peak value of short-circuit current are called current-limiting fuses. Current-limiting fuses only have a good operating life of half a wave.

HRC fuse link working principle

Under normal circumstances, the electrical current does not generate enough heat to dissolve it. If the current passing through exceeds its limit, the fault current will melt before the element of the fuse reaches its peak value. When a fuse is in an overload condition, the fuse components will not melt, but if this continues for a long time, a material like eutectic can melt and destroy the fuse element.

When a fuse is in a short circuit condition, the thinner portion of the fuse element melts faster over a smaller area. It will break before the eutectic material. Therefore, HRC is justified in providing limits within the fuse element.

Applications of HRC fuses

● Used to protect high-voltage switchgear from short circuits.

● For backup security.

● This type of fuse is also used in motor stators.

● Used for the protection of motors, transformers, automobiles, and other electrical appliances.

Reasons for a blown HRC fuse link

1. Short circuit: A short circuit fault occurs on the line side and the fuse blows quickly;

2. Overload: The load current exceeds the rated current of the fuse, and the fuse heats up and blows out for a long time (usually 1.1 times the rated current blows out in about an hour)

3. Pulse: When the circuit is started or the power supply is unstable, an instantaneous large current causes the fuse to break; in addition, the screws are not tightened when the fuse is installed, or the fuse is damaged, which can also cause the fuse to blow.

4. There is a difference between a current short circuit and a current overload: a current short circuit is a direct connection between the live wire and the neutral wire without passing through electrical appliances, quickly generating an almost unblocked current loop. When an extremely large current passes through the fuse, the resistance of the fuse suddenly increases and heat energy is generated. Being blown off immediately;

What to do after the HRC fuse link is broken

1. Turn off the power immediately

When the fuse blows, the power supply should be cut off immediately to avoid damage to electrical equipment or accidental personal injury.

2. Check the cause of the failure

Then, it is necessary to check the cause of the failure of the electrical equipment and circuits, find out and solve the fault, and prevent another fuse accident from happening again.

3. Replace the fuse

If it is determined that the problem is caused by a blown fuse, the fuse will need to be replaced. Be sure to use a fuse of the same type and current rating as the original to ensure the safety and reliability of the circuit.

4. Reconnect the power supply

After replacing the fuse, reconnect the power supply and check whether the circuit is operating normally to prevent another accident.

5. Test

Finally, test verification is performed to ensure the safety and reliability of circuits and electrical equipment.

Protection measures to prevent HRC fuse link blowing

To prevent the occurrence of fuse-blowing accidents, the following measures can be taken:

1. Select the fuse correctly and choose the appropriate fuse according to the rated current of the circuit.

2. Regularly check electrical equipment and circuits, and promptly eliminate short circuits, overloads, and other faults to ensure the safety and reliability of circuits.

3. Reasonably install protection devices in the circuit, such as over-current protection devices, short-circuit protection devices, etc., to improve the safety of the circuit.