How Does a HRC Fuse Work?

In the complex landscape of electrical systems, a High Rupturing Capacity (HRC) fuse stands as a cornerstone of safety, playing a pivotal role in safeguarding electrical circuits and equipment from the perils of excessive current. A comprehensive understanding of its operational mechanism is not only fundamental for electrical engineers but also crucial for anyone involved in the installation, maintenance, or use of electrical systems.

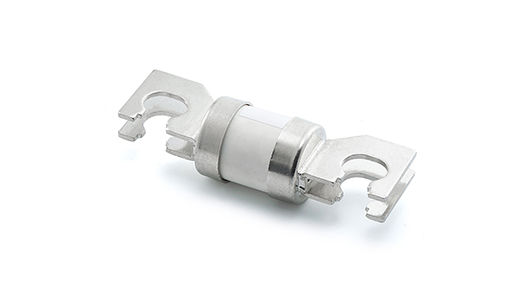

Structure of an HRC Fuse

At its most basic level, an HRC fuse is composed of a specialized conducting element, typically crafted from silver. This highly conductive metal is chosen for its ability to efficiently carry electrical current under normal conditions. The silver conductor is then enclosed within a hermetically sealed body, which provides a protective barrier against external elements. Inside this body, the space around the conductor is filled with a specific type of material, often quartz powder. This unique construction equips the HRC fuse to handle high - current scenarios with precision and reliability.

Normal Operation

During normal electrical system operation, the current flowing through the HRC fuse remains within the specified rated capacity. Thanks to the low - resistance properties of the silver conductor, the electrical current passes through it smoothly, much like water flowing through a well - maintained pipe. This seamless flow of current enables electrical energy to reach all connected devices without any hindrance, ensuring the uninterrupted operation of the electrical system.

Response to Abnormal Current Conditions

Over - Current Situations

When an over - current occurs, where the electrical current exceeds the normal operating level but is not as extreme as in a short - circuit, the HRC fuse's response mechanism is gradually activated. The increased current causes the silver conductor to heat up. As the temperature of the conductor rises, its resistance also begins to increase. This rise in resistance further contributes to the generation of heat, creating a self - perpetuating cycle. However, the HRC fuse is designed to withstand this gradual increase in heat for a certain period, depending on its rating.

Short - Circuit Scenarios

In the case of a short - circuit, which is characterized by an instantaneous and massive surge of current, the response of the HRC fuse is immediate and dramatic. The intense heat generated by the extremely high - level current causes the silver conductor to melt almost instantaneously. The silver transitions from a solid to a liquid state in a fraction of a second. This melting of the conductor effectively breaks the electrical circuit, halting the flow of current and preventing potential damage to the electrical equipment and the circuit itself.

The Role of Filling Material

The filling material within the HRC fuse, such as quartz powder, is of utmost importance. When the silver conductor melts during an over - current or short - circuit event, the quartz powder comes into action. It reacts with the silver vapor produced during the melting process. This chemical reaction results in the formation of a high - resistance substance. This high - resistance material is crucial for quickly extinguishing any arcing that might occur. Arcing is a dangerous phenomenon because it can maintain the flow of current even after the conductor has melted, potentially leading to further damage or even a fire. By suppressing the arc, the HRC fuse ensures that the electrical circuit is completely and effectively interrupted. Additionally, the filling material also absorbs a significant amount of the heat generated during the melting of the conductor. This heat - absorption property helps in cooling down the fuse, protecting it from damage and preventing any potential harm to the surrounding electrical components.

Conclusion

In summary, the HRC fuse is a deceptively simple yet highly effective electrical safety device. It protects electrical systems by breaking the circuit when excessive current flows, relying on a combination of a melting conductor and an arc - suppressing filling material. Its proper functioning is essential for safeguarding electrical equipment, preventing electrical fires, and ensuring the safety of individuals in various electrical installations, from industrial facilities to residential buildings.